|

|

There are a few easy things you can do to help keep your machines last in the field longer. These tips won't work miracles, but they can help keep your equipment out longer before you need to send it in to be serviced. All you need is a damp rag, some canned air, and the time to clean your machines. You can apply these tips to most validators and coin mechs. As an example we used an old MEI VN 2512, TRC-6800, and Coinco BA30B.

|

|

|

|

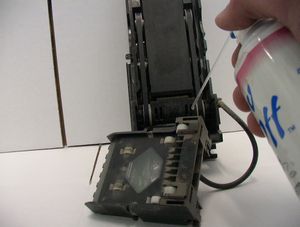

The VN 2512 was extremely dirty. First we removed the bill magazine and blew out the whole unit and LED housing with the canned air. This can help remove dust from many of the sensor windows.

|

|

|

|

Next we cleaned the LED housing windows with a damp rag. It is also good to wipe away as much grime off of the pinch rollers as you can.

|

|

|

|

Next you can wipe off the Sensor housing window and belts with the damp rag.

|

|

|

|

Finally you can wipe off the prism and blow out the magazine. Again these tips won't work miracles, but they can increase longevity.

|

|

|

|

This TRC-6800 was incredibly dirty also. A coin mech's coin path needs to stay clear of dirty and debris. You can pull back the lid and wipe the coin path down with your damp rag. This helps on most older coin mechs.

|

|

|

|

Next we blew the dust out of the acceptor and the coin tubes. Make sure not to get the coin tube sensors wet. It can short them out.

|

|

|

|

What a suprise, another dirty old bill validator. This Coinco BA30 was also extremely dirty. We started by taking off the magazine and pulling out the lower assembly. We wiped the sensors and belts off with a damp rag then blew out the assembly with our air.

|

|

|

|

We then reached in the main assembly and wiped off the sensor windows and belts.

|

|

|

|

Next we blew off the insides and outsides of the bill acceptor. Coinco's have many sensors which can be affected by dust. This can help keep your equipment in the field longer.

|